Do you want to produce your own floating fish feed or set up a fish feed plant? Welcome to Liren Feed Machinery. Liren Feed Machinery is an industrial group mainly specialized in feed pellet machinery.Various types, models and output of fish feed machines and fish feed production lines for your choice!

Get More Details

Established in 1998, Zhengzhou Liren Technology Co., Ltd.is a professional feed machinery manufacturer and supplier in China. We are mainly engaged in the R&D and manufacturing of equipment such as fish feed, poultry feed, livestock feed, and pet food. With 24 years of professional design production and installation experience in the feed machinery industry, and have gradually formed a complete R&D, production, sales, and service system, providing technical solutions and supporting products. At present, the marketing network of Liren Machinery has spread to more than 100 countries and regions in Africa, Asia, Europe, America, and Oceania.

This fish feed making machine is used to produce different sizes of fish feed pellets, The screw of the machine is made of chromium alloy steel and undergoes special heat treatment. long service life and wear-resistant; The motor uses a standard pure copper motor that is stable and durable, and Siemens motors can be customized; The fuselage uses environmentally friendly spray technology to resist corrosion and not easy to rust; The Machine body made of high-thickness steel plate, strong and stable, not easy to damage; This machine can make different size from 1mm-12mm ,suitable for different stage of fish.

This dry-type floating fish feed machine is driven by a diesel engine, Equip the diesel engine can solve the problem of electricity shortage and electricity not stable.

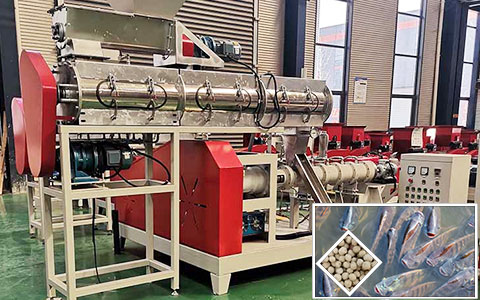

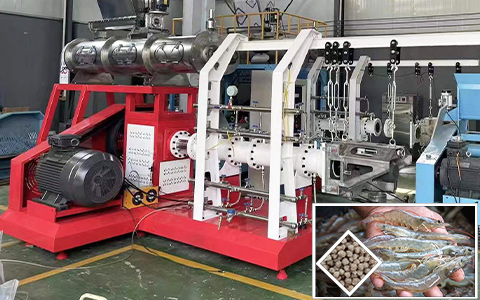

The wet-type fish feed pellet machine is equipped with a preparation device to ripen the feed raw materials and is usually used for large-volume production of feed lines for use with boilers. it can produce neat and uniform beautiful ultra-small diameter particles, has a good self-cleaning effect, no need to disassemble, good ripening degree, has high water content, wide application range, can produce high oil, high moisture materials, mainly used in aquatic feed, pet food and animal feed.

The twin screw fish feed extruder has large output, fast extrusion speed and low energy consumption per unit output.It could make all kinds of fish feed formula, and it also with self-clearing screw system, to avoid feed Cross-contamination, The capacity of twin screws working for a long time is more stable. It is wider and more economical than single screw extruder.

The small fish feed production line is cheap and simple operation, Easy to move, small size, Low transportation cost, pellet size could be chosen from 1-12mm

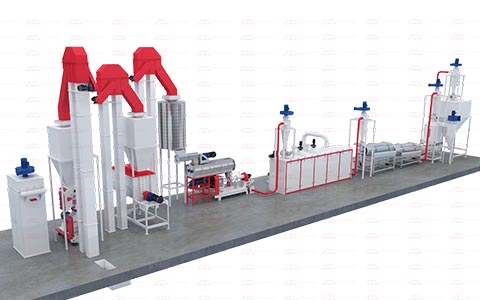

The Complete Floating Fish Feed Production Line is suitable for medium/big farm and commercial fish feed factory, Long working life, make high protein feed, Stable output, high efficiency, continuous work, labor saving, can pack directly, pellet size could be chosen from 0.8-12mm

The Complete Fish Feed Processing Line is suitable for medium/big farm and industrial production, Long working life, make high protein feed, Stable output, high efficiency, continuous work, labor saving, can pack directly, pellet size could be chosen from 0.8-12mm

A complete fish feed pellet production line from raw material processing to final finished pellets consists of a crushing system, drying system, pelletizing system/extrusion system, spraying system, cooling system, and packing system. Liren Feed Machinery provides comprehensive services for the entire life cycle of fish feed pellet plants. Space-saving structure. Optimize production plans.

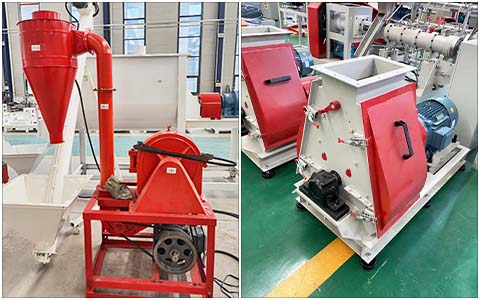

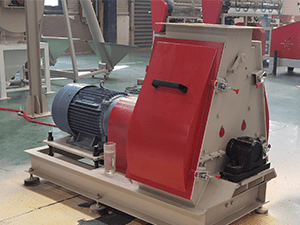

According to the size and production capacity, it can be classified into 9FQ Hammer Mill and Water drop Hammer Mill. 9FQ Hammer Mill is used for crushing grain, straw, hay, etc. The hammer is used in a wide range. It is used in poultry and livestock feed production lines. Water drop Hammer Mill is a general-purpose product with stable performance, which is widely used in the crushing of raw materials in large and medium-sized feed factories.

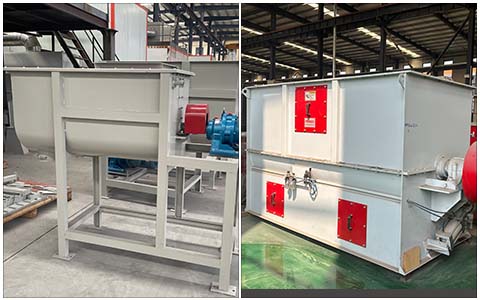

The animal feed mixer machine is used for mixing powder raw materials, high mixing coefficient, U-shaped design, no residue, mostly used in feed production lines over 300kg.

The Feed Dryer Machine is used to reduce the moisture content of the feed so that it can be packaged for long time storage for sale. According to the production capacity, it can be classified into Vertical dryer and Horizontal dryer, the Vertical Dryer suitable for small manual feed production lines. the Horizontal Dryer suitable for Commercial automated feed production line.There are steam type and electric type optional, fully enclosed design double heating pipeline, high drying efficiency, stable effect, can effectively reduce the humidity to 10%.

A large complete fish feed plant need a lot of different equipment, the main feed equipment include:

Fish feed grinder widely used for grinding the raw material such as corn to 3-5mm powder. The raw material can be choose grain , grass and others.

Fish feed mixer widely used to mix powdered materials to make the components of the mixture evenly distributed and ensure the quality of compound feed.

Fish feed pellet machine As the most important equipment , fish feed pellet machine used for making different size fish feed pellet.

Production will be arranged immediately after receiving the prepayments in 24 hours. The deadline of every process will be controlled strictly to guarantee a short delivery time.

Trust comes from quality and service. we have our own factory, professional processing equipment, high-quality products, and good pre-sale and after-sale service. We can custom design machines and lines of different capacities according to your budget, your raw materials, your final feed requirements, and your workshop size. we take the time to know your unique requirements, and then we work with our engineers to recommend the perfect solution for you. If you want to buy a fish feed extruder machine or built a fish feed plant project, Liren is your good choice.

Established in 1998

24+ production experience

200+ cooperative partner

32000+ factory workshop area

500+ employees

the company's performance has gradually increased and it has exceeded 2 billion yuan

We adopt world-famous brand for the key electronic elements, pneumatic and hydraulic system to ensure high quality and reliability of the feed machinery.

All products have passed ISO9001, CE, PC, and SGS international authentication.

Highly advanced processing equipment could promise high-quality machines

Trust comes from good quality and service.

Quality test before delivery

Engineer support

Provide free spare parts

Provide free feed formula

One-year warranty

Find us at any time through multiple channels

We make sure your machine working very well 100%.

Our customers come from more than 100 countries and regions in Africa, Asia, Europe, South America, North America, Oceania.

Africa: Nigeria, Ghana, Cameroon, Malawi, Tanzania, Uganda,Côte d'Ivoire, Zambia, Benin, Kenya, Botswana, Zimbabwe, Ethiopia, Rwanda, Democratic Republic of Congo, Niger, Gambia, Angola, Ethiopia, Mali, Gabon, etc.

Asia: Thailand, Sri Lanka, Bengal, India, Pakistan, Indonesia, Bahrain, Malaysia, Saudi, Arabia, Uzbekistan, Indonesia, Georgia, Cambodia, China, etc.

South America: Argentina, Bolivia, Ecuador, Suriname, etc.

North America: Dominica, Canada, U.S., Mexico, Guatemala, etc.

Europe: Germany, Russia, France, Romania, Switzerland, Slovakia, Romania, Morocco, etc.

Oceania: new Zealand

Model: LM50

Capacity(kg/h): 80-100 kg/h

Power(kw): 11kw

Weight(kg): 320kg

Machine size(mm):1470×1100×1250

Model: LM60

Capacity(kg/h): 100-150 kg/h

Power(kw): 15kw

Weight(kg): 350kg

Machine size(mm):1470×1100×1250

Model: LM80

Capacity(kg/h): 200-300 kg/h

Power(kw): 86kw

Range of application: small/medium commerical Aquatic /pets feed factory, big farm

Main machines: crusher - conveyor - mixer - feed pellet extruder -dryer - seasoning machine - cooler - finished product silo - Packing and seal machine

Model: LM200

Capacity(kg/h): 1-2 t/h

Power(kw): 132kw

Range of application: small/medium commerical Aquatic /pets feed factory, big farm

Main machines: crusher - conveyor - mixer - feed pellet extruder -dryer - seasoning machine - cooler - finished product silo - Packing and seal machine

Liren Feed Machinery is a leading feed equipment manufacturing pioneer in China, with strong technical background, professional resources and the ability to quickly respond to customer needs. Our aim is to serve every customer sincerely, and we are very confident to provide a strong guarantee for the efficient operation of our equipment. We promise a one-year after-sales warranty, and we are always ready to help customers solve every problem in various ways, such as installation problems, abnormal operation failures, etc. In addition, we can provide professional operation instructions to customers who have little experience in operating our equipment in a short period of time.